Process Gas Systems

工艺气设备系统

在石化行业中,采用普里森膜系统回收氢气和调整合成气组分以提供生产效率。膜分离器从高压石化气体弛放气中,利用其选择渗透原理回收和提纯氢气,除掉掉惰性气体;氨气是合成气在催化反应器中产生的。合成气由氢气,氮气和其他惰性组分如甲烷和氩气组成的。氨的转化在第一次的反应中是不完全的,因此需要合成气在合成塔中循环反应。这个过程会导致惰性组分的积累并需要从合成塔中放掉,而所放掉的气体中还含有高浓度的合成气组分,就可以用PRISM膜系统来处理此股弛放气,以回收氨作为产品并将回收的氢气返回到合成回路。

PRISM Membrane Systems recover hydrogen and adjust synthesis gas streams to provide maximum efficiency at petrochemical processing plants. The membrane separators use selective permeation to recover and purify valuable hydrogen or reject inert byproducts from high-pressure petrochemical streams. Ammonia is produced by introducing a synthesis gas stream into a catalytic reactor. The synthesis gas is comprised of hydrogen, nitrogen, and inert byproducts like methane and argon. Ammonia conversion does not completely synthesize in the first pass, so the process requires the components to be looped through a cycle. This process causes the inert byproducts to accumulate and purge. The resulting purge gas contains high concentrations of the synthesis gas components. PRISM Membrane Systems treat the purge stream by recovering ammonia as the product and returning the hydrogen to the synthesis loop.

HYCO比例调节系统

HyCo ratio adjustment system.

炼油厂中加氢裂化尾气的处理

Refinery Hydrocracker Off-Gas treatment

甲醇弛放气氢回收 - 石化行业的应用

Hydrogen Recovery from Methanol Purge - Petrochemical application

.png?crc=142287121)

最早的第一套普里森膜系统实际应用是在1977年,在甲醇合成中使用PRISM膜分离器调节氢气与一氧化碳的比例。因为原料气处理后基本上与合成回路压力相同,而且氢/一氧化碳比可以容易地调节,所以膜分离是非常适用于此工艺要求。

The very first PRISM Membrane System was built for this exact application in 1977. PRISM Membrane separators adjust the hydrogen to carbon monoxide ratio in oxo-alcohol synthesis gas streams. Membrane separation is a good fit for this application since the feed gas is treated at essentially the same pressure as the synthesis loop pressure. The hydrogen/carbon monoxide ratio can be easily adjusted to meet specific process requirements.

普里森膜系统是在炼油厂的加氢重整中氢气回收的关键组件,它们分离去掉了氢气循环回路中的惰性组分,这意味着只需要制造较少的新氢气就可保持系统中的氢平衡。通过回收氢气的循环使用,可以大大降低系统运行的成本。

PRISM Membrane Systems are a key component in recovering hydrogen within hydroprocessing applications at oil refineries. They reject the inert compounds that build up in hydrogen recycle loops. This means that less manufactured hydrogen is required to maintain the hydrogen balance in the system. By refreshing the hydrogen loop, the process becomes less costly to operate.

.jpg?crc=510611304)

甲醇是合成气在催化反应器中合成的,合成气由氢气、一氧化碳、二氧化碳和惰性组分如甲烷、氮气和氩气等组成的。甲醇的转化在第一次的反应中是不完全的,因此需要合成气在合成塔中循环反应。这个过程会导致惰性组分的积累并需要从合成塔中放掉。

Methanol is produced by introducing a synthesis gas stream into a catalytic reactor. The synthesis gas is comprised of hydrogen, carbon monoxide, carbon dioxide, and inert byproducts like methane, nitrogen, and argon. Methanol conversion does not completely synthesize in the first pass, so the process requires the components to be looped through a cycle. This process causes the inert byproducts to accumulate and purge.

使用普里森膜分离系统处理此驰放气,将甲烷气体作为产品气体并将氢气返回到合成回路。

PRISM Membrane Systems treat the purge stream by separating methanol as the product gas and returning the hydrogen to the synthesis loop.

.jpg?crc=4075028939)

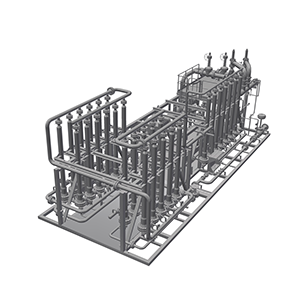

[见下面图片]:氢气膜分离器由很多中空纤维丝组成,它的尺寸可达到直径200毫米、长3米。此膜组件安装在与需要分离的气体压力相匹配的钢制压力容器内。此压力容器可单级安装或成排多级安装。通过切断每个膜分离器下的阀门就可以在不影响各分离器性能的前提下实现膜分离装置从0到系统最大流量的操作。

Process gas separators consist of very large membrane bundles, that are up to 200 mm in diameter and 3 meters long. The bundles are encased in a coded pressure vessel specific to the pressure rating and gas separation required. The pressure vessels are arranged in banks that can have single or multiple stages. By valving off individual separators, the plant can operate at less than maximum flow without adverse effect on separator performance.